——AI-FORM STRETCH FORMING——

——蒙皮拉形零件工艺设计与仿真软件——

——Design & Simulation Software for Skin Part Forming——

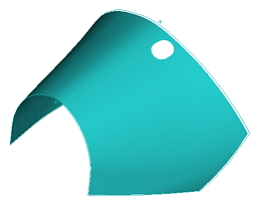

- AI-Form Stretch Forming (AISF) 是一个专注于蒙皮拉形工艺的软件包,将 CAD 设计、工艺过程机构运动学分析和 有限元 模拟有机地结合在一起。

- AISF 采用了最新的数值模拟技术,充分考虑到蒙皮坯料大变形大位移的真实力学行为,具有很高的计算精度和高效的模拟速度。

- AISF 的分析计算包括两个阶段:拉形机的机构运动过程仿真和板材变形的有限元模拟,进而设计和优化拉形成形过程中的工艺参数。

- AI-Form Stretch Forming (AISF) is a whole package to combine the CAD design, kinematic process design and FEM simulation together to serve the stretch forming process.

- AISF using the latest numerical simulation technology and taking into account the real behavior of the blank sheet deformation, with high accuracy as well as faster simulation.

- AISF works in two stages of simulation: the kinematic process simulation and finite element simulation to design stretch forming process and create the part program.

Geometry process

Die design

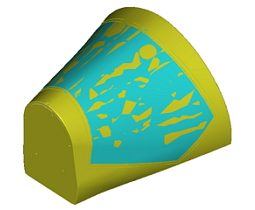

Kinematic Processing

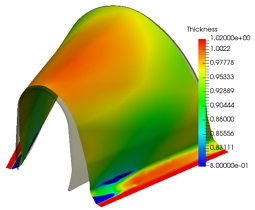

FEM Simulation

——主要特点——

AISF MAIN FEATURES & APPLICATIONS

工艺设计

Process Design

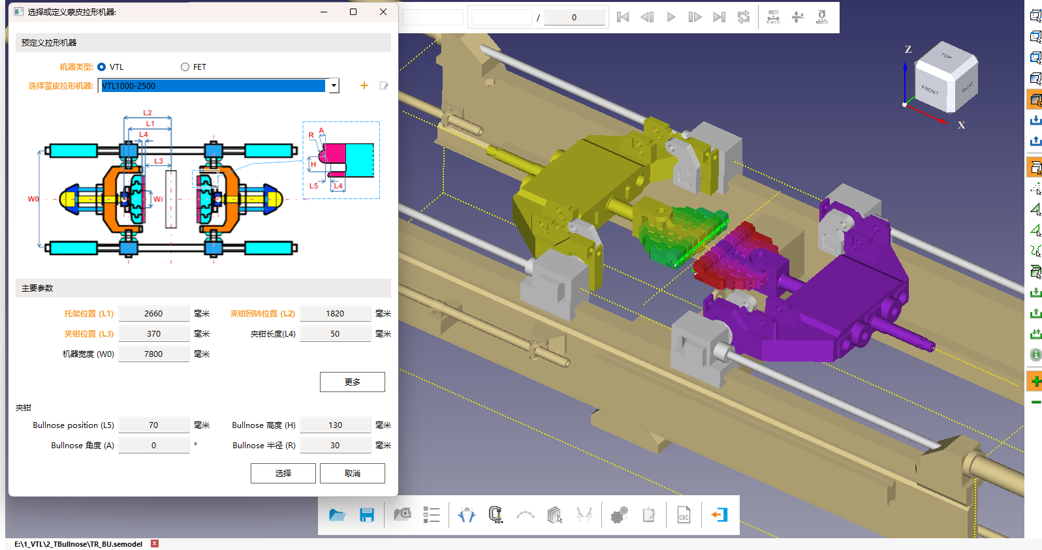

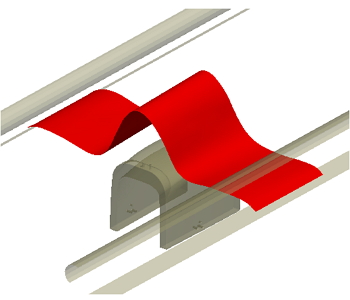

- 支持各种蒙皮拉形成形工艺,内置有横拉、横拉牛鼻子、纵拉等设置模板。

- 包含通用VTL系列和FET(FETM)系列拉形机的机器数据库,用户也可以自定义机器。软件包中还包含特定的授权机器数据。

- 方便灵活的夹钳设计,夹钳的大小、数量、宽度和间隙都可以任意设定。

- 内置向导用于设定夹钳间的角度,可依据零件形状和特征线曲率进行选择或设计。

- 方便的工序管理功能。工序数目不受限制,子工序可灵活排序。根据不同拉形工艺,预置了不同的机构运动模板,如预拉、包覆、补拉、释放等。

- 自动工序设计工具。根据用户定义的总塑性应变以及每个子过程的应变分配,自动设计机构运动轨迹,尽可能地满足相切的轨迹条件。

- 内置热处理向导,分析成形过程是否需要进行热处理,并指导用户将拉形过程分解成尽可能少的工步。

- Support all kind stretch forming process, such as transversal wrap, transversal bullnose and longitudinal stretch.

- Build in database with the common VTL series stretch forming machine, also accept the user’s defined machine.

- Flexible jaw design function. The jaw’s number, location, width and gap could be customized.

- Based on the part geometry, build-in wizard to design the curvature angle of jaws.

- Powerful process management function. All sub-processes are managed in one table, easy to sort the sequence and modify the parameters. Pre-defined templates for difference process.

- Build in tools to predict the kinematics trajectory as the part geometry and given total plastic strain as well as the strain distribution of each sub-process.

- Build in heat treatment wizard, guide the user to separate the stretch forming runs as the maximum plastic strain and define the heat treatment process.

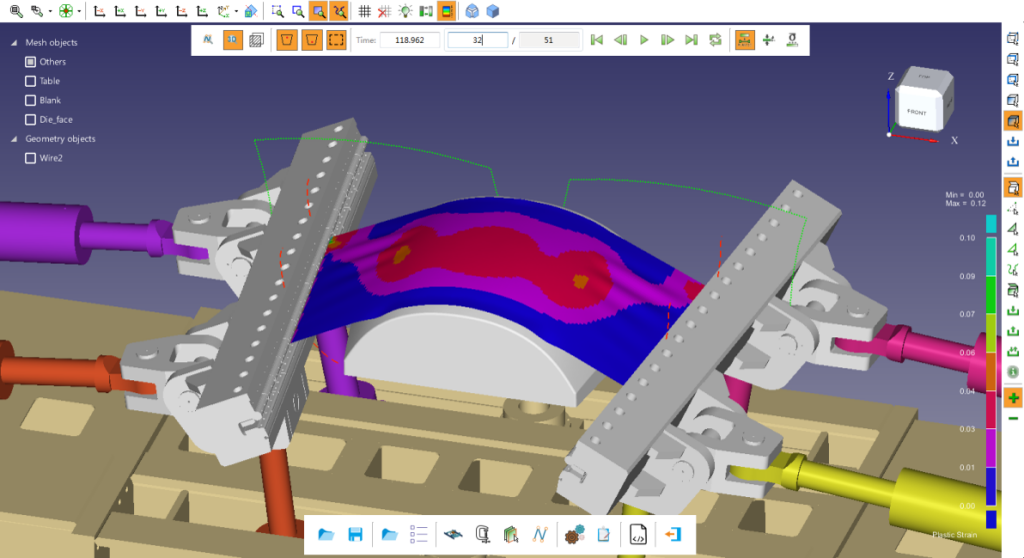

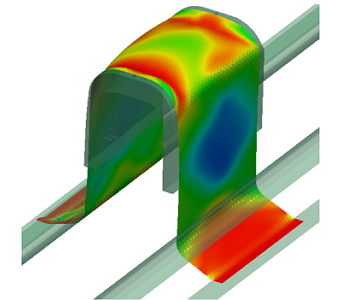

- 采用最新的有限元模拟技术,能模拟蒙皮拉形过程的力学变形行为。节省昂贵的“试错”成本。

- 能对成形过程中的问题进行分析,如材料变形、破裂、起皱、桔皮与回弹等各种问题。

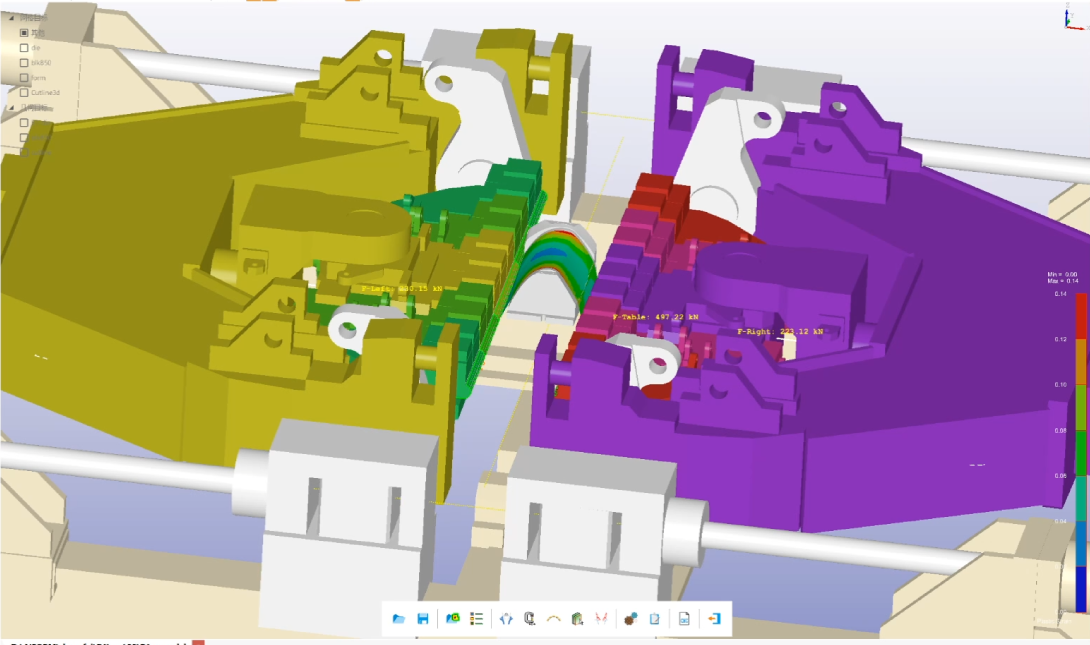

- 能分析零件成形的可能性和机器吨位是否合适。

- 可以使用逆算法获取最优的板材尺寸。

- 基于模拟结果,可以指导模具设计和工艺参数设计,并充分利用机床的加工能力。

- 基于最终的零件形状与质量要求,创建和优化所有运动机构的运动轨迹,提升最终产品质量。

- 独特的边界加载方法,计算效率较传统有限元方法提升30%以上。

- 支持高级接触计算方法,支持物理夹钳的模拟。

- 采用独特的技术,支持热处理工艺的模拟,充分考虑加载历史和热处理对材料性质和应力应变对影响。

- Simulating the stretch forming processes, taking into account the kinematics of the machine to save cost and time on the ‘trial and error’.

- Predicting the technological failures of the forming process, such as rupture, wrinkles, orange peel and springback etc.

- Check part feasibility on a given machine.

- Optimizing stretching parameters in order to minimize the sheet sizes, build-in inverse solver for blank sheet flatting.

- Checking part balancing on the machine, and support the die design.

- Create and optimize the trajectory movement of all moving axis according to the deformation required on the sheet to improve part quality.

- Support advance contact calculation for the translation and rotation contact surface, support physical Jaw simulation.

- Support heat treatment process design and simulation.

- Parallel computing to save CPU time.

CAM &工程报告

CAM & Engineering Report

- 根据设计的工艺参数和使用的机器数据自动生成工程报告。

- 该报告可直接用于工业生产,并支持多语言。

- 对于授权的指定拉形机器,可以直接将设计的工艺参数直接转化成 NC 代码用于生产加工。

- Generate engineering report based on the machine data and designed process parameters automatically, support multi-language as well.

- Generate a part program which control all kinematic axes of the machine.

- Generate NC programs for CNC of the given stretch forming machine.

核心价值

User Benefits

- 提高蒙皮拉形零件的质量和可重复性,能处理复杂零件。

- 大大优化工艺质量,缩短工艺制定时间,提高生产力。

- 增强对蒙皮拉形内在过程的理解。

- 采用软件使经验知识系统化,科学化,可传承和发展。

- Increases repeatability & part quality

- Enables complex part forming

- Optimizes industrialization time

- Improves productivity and cost structure

- Enhance engineering knowledge of stretch forming.

- Easy to use software and short learning curve.

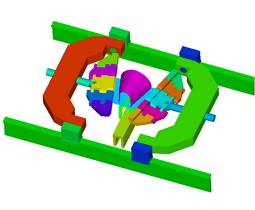

——虚拟机床——

Virtual Machine

- 软件内置数台拉形设备,包含设备参数和运动关系,支持常见的VTL系列和FET(M)系列机床。

- 可以定制特定授权的拉形设备。

- 可以自定义设备和扩充数据库。

Thanks to the machine database, a virtual machine is available in any time. It could be used for sub-process design and the device motion check.

——特色功能——

SALIENT FEATURES

- 专项开发: 软件专为蒙皮拉形工艺“私人定制”。

- 机构运动: 所有的边界条件直接施加在运动机构上,而非传统CAE软件的板料节点上。

- 虚拟机床: 在工艺制定过程中和工艺校核过程中随时提供虚拟机床,任何设置的问题即时发现。

- 工业语言: 软件界面完全工业化,直接使用工业语言.

- 自动设计: 内置设计工具依零件形状和特征线自动生成机构运动轨迹,较传统经验方法迅速而可靠。

- High Orientation Development: Special developed for skin stretch forming process with the given style stretch machine.

- Machine Kinematics: Software customized to machine kinematics.

- Virtual Machine: provides the virtual machine during the process design stage as well as result checking.

- User Friendly: Special designed interface for stretch forming, uses industrial language.

- Auto Design: Build in design tools to generate the kinematics trajectory automatically.

——工艺设计——

Smart Design for Sub-process Design

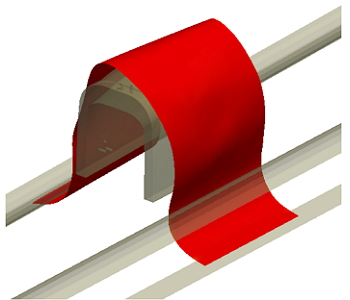

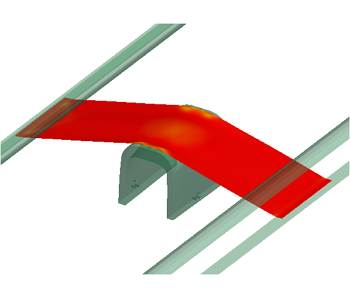

拉形过程模拟 (工艺依经验制定)

Stretch forming process simulation (Designed by experience)

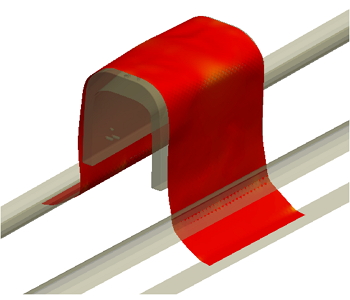

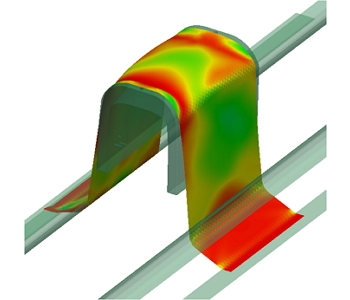

拉形过程模拟 (工艺依自动制定 )

Stretch forming process simulation (Designed by Smart Design)

关注微信公众号

关注微信公众号